What is Automated Forklift Controller?

A computerised system designed to run a forklift or similar material handling equipment without human involvement is known as an automated forklift controller. This controller navigates, manipulates, and transports things inside a defined region, such as a warehouse or distribution centre, using a combination of sensors, algorithms, and programming. An automated forklift controller’s primary purpose is to increase efficiency, reduce human labour, and improve safety in material handling activities. It can perform activities including picking up and arranging products, navigating past barriers, and optimising transport routes. The capabilities of the controller might range from simple predefined routes to more advanced systems that combine real-time data processing and decision-making to adapt to changing surroundings.

upgrade your existing Forklift fleet to autonomous operation

When you have exsiting forklift fleet that is still in good service status and there are requirement to upgrade to unmanned operation, then LiDAR Solutions Australia is able to provide modification or retrofit service by add premium automatic navigation and control system and sensors to upgrade your manned system to unmanned operation.

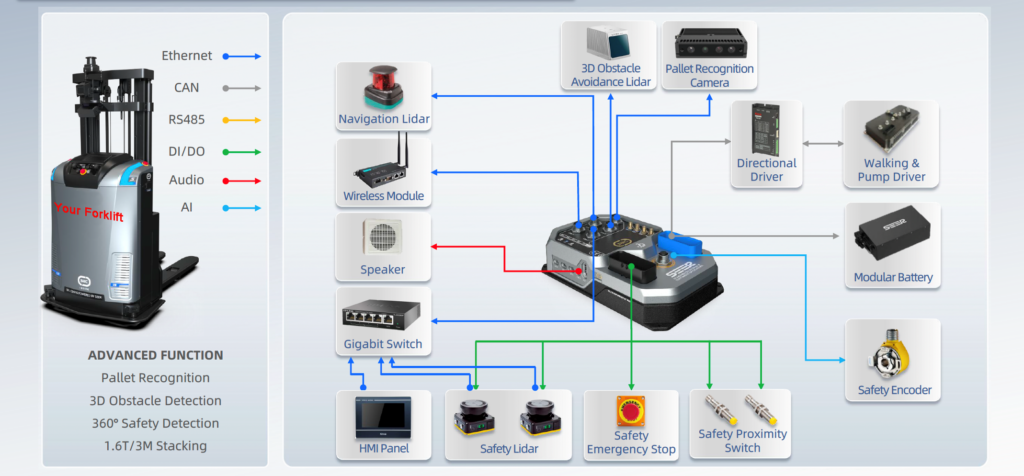

Key features of our AGV Forklift control system:

2m/s speed, specifically for forklift

The speed can reach 2m/s, high speed and high efficiency. Integrate various special functions for forklifts, such as single steering wheel models, fork pick and place, pallet recognition, variable wheelbase models, 3D obstacle avoidance, obstacle bypass, AI QR code recognition, single garage management, storage area pick and place, etc. Function. Empowering rapid car manufacturing and fast delivery, mass parts adaptation, free model selection, worry-free car manufacturing.

±2mm high precision, precise and stable

Supports SLAM, reflector/column features, and feature point cloud positioning and navigation, with an accuracy of up to ±2mm, and high consistency of multi-vehicle accuracy; high environmental adaptability, stable operation in environments with 30% low map confidence; optimized skid detection and processing strategies to avoid the reduction of vehicle body skid navigation accuracy.

Automatic route optimization, smooth and efficient

Improve the handling efficiency by 40%, support automatic batch optimization of routes, double the absolute accuracy at most, and make the movement of the car body more coherent and smooth.

New calibration technology, smart and easy to use

The new calibration technology supports the calibration of all single-rudder type forklifts, and can automatically search for unqualified calibration items to improve calibration efficiency; it supports online calibration of the zero position of the rudder angle, which is more convenient.

Controller is certified functional safety, CE, UL dual certification

The only mobile robot controller in the world that has passed functional safety certification; it has passed many standard tests such as IEC 61508, IEC 62061, ISO 13849, EN 61010-1, EN61326-1, EN 300328, EN 300440, UL61010-1, UL 61010-2-201, 47 CFRPart 15, and obtained CE-EMC, CE-LVD, CE-RED and other CE certification certificates and UL standard ETL certificates.

architecture of AGV forklift control system